The VHM Seal of Quality

Where data-driven analysis and expert oversight guarantee flawless results for every meter of fabric.

Quality is Not an Act, It's Our Process

At VHM, quality is not a final inspection—it is a philosophy woven into every stage of our operation. From raw material inspection to final dispatch, our dedicated Quality Hub acts as the nerve center, ensuring every decision and output adheres to the highest standards of excellence.

Inside Our World-Class Laboratory

Spectrophotometer

The cornerstone of modern color matching. This instrument creates a digital "fingerprint" of any color, allowing for data-driven recipe prediction and guaranteeing unparalleled lot-to-lot consistency.

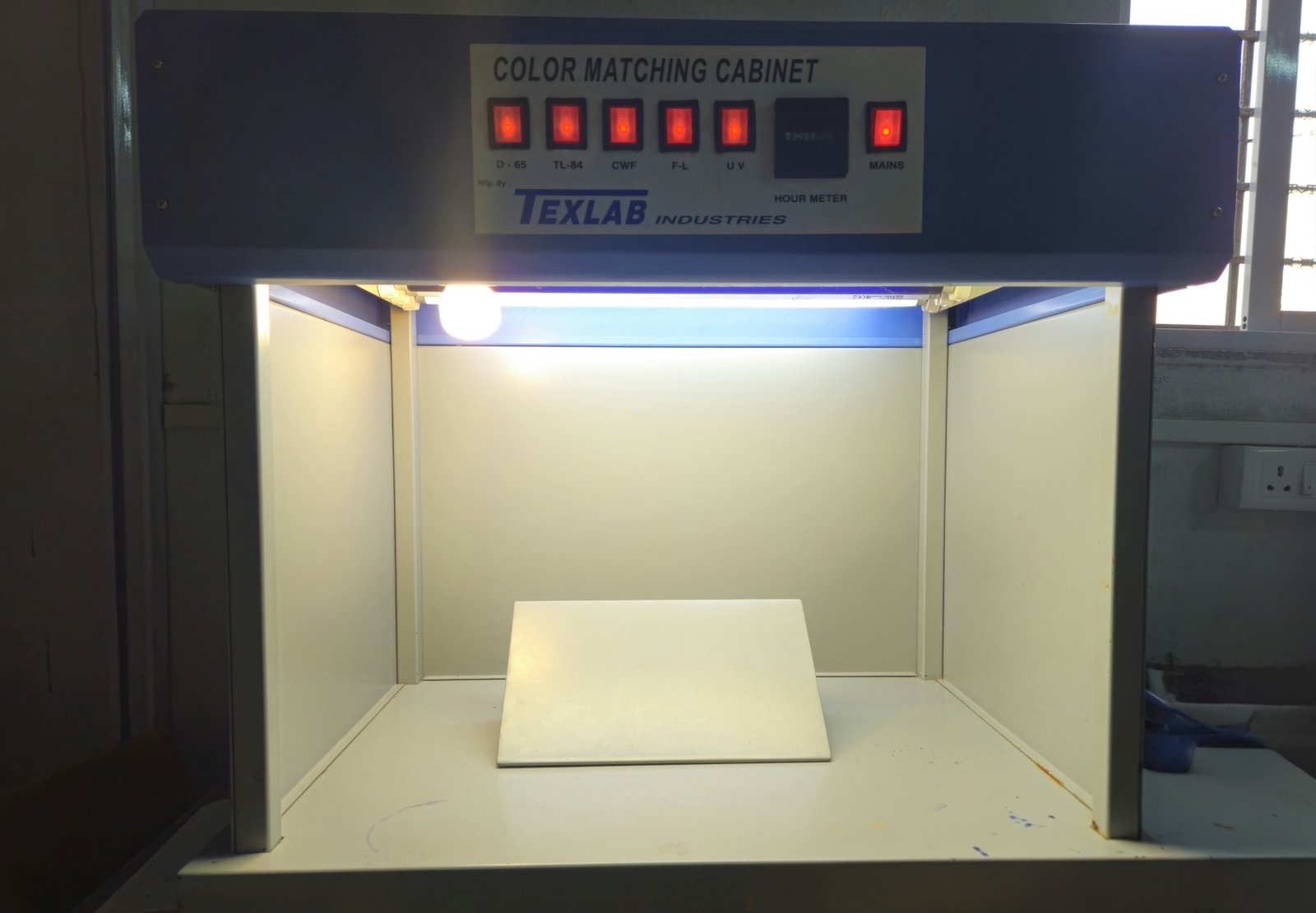

Color Matching Cabinet

Provides standardized lighting conditions (D65, TL84, etc.) to eliminate metamerism and ensure color appears consistent in showrooms, homes, and outdoors.

Infra Color Dyeing Machine

A state-of-the-art machine for rapid, waterless lab dyeing. Its accuracy allows us to develop and approve color samples faster than ever before.

HTHP Glycerin Bath Beaker Dyeing

Essential for developing precise dyeing recipes for synthetics like polyester, which require high-temperature and high-pressure conditions to achieve deep, vibrant shades.

Rota Beaker Dyeing Machine

Our workhorse for general-purpose lab dyeing. A versatile and reliable machine for developing recipes across a wide range of fabrics and colors.

Water Bath with Dye Pot

Used for standard atmospheric dyeing tests and experiments, perfect for cottons and other natural fibers.

Tensile Strength Tester

Measures the breaking strength, elongation, and seam slippage of fabric, ensuring it meets the rigorous durability standards for its end use.

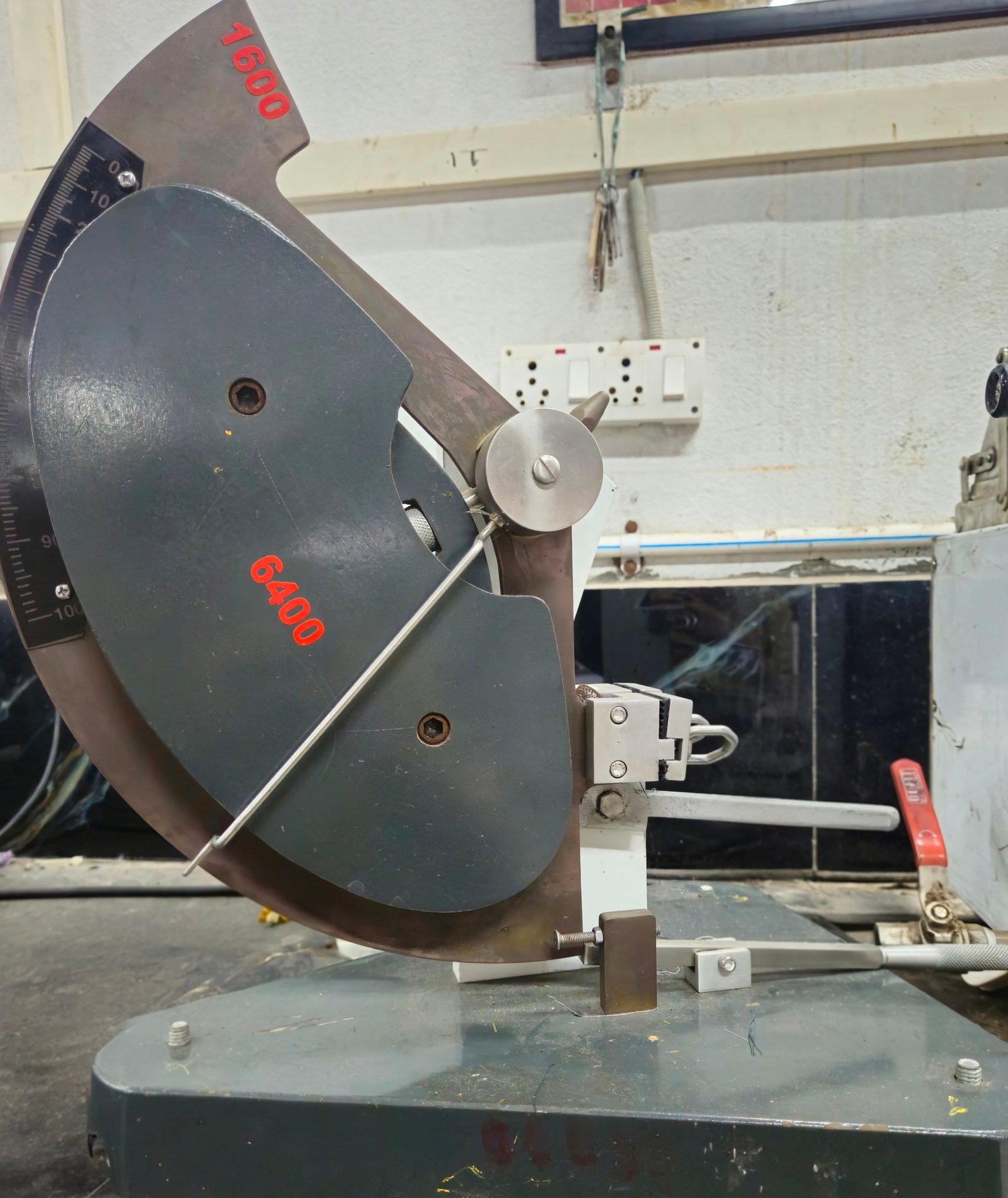

Tear Strength Tester

Determines the fabric's resistance to tearing under stress, a key indicator of toughness and longevity for high-performance apparel and upholstery.

Pneumatic Padding Mangle

Perfectly simulates our full-scale padding and finishing processes, allowing us to accurately test chemical finish recipes and ensure uniform application.

GSM Cutter

Precisely cuts fabric swatches to determine the fabric's weight (Grams per Square Meter), a critical parameter for meeting client specifications and ensuring consistency.

Hot Air Oven

A versatile tool for various tests, including evaluating finishes after curing, heat setting trials, and determining the moisture content of fabric.

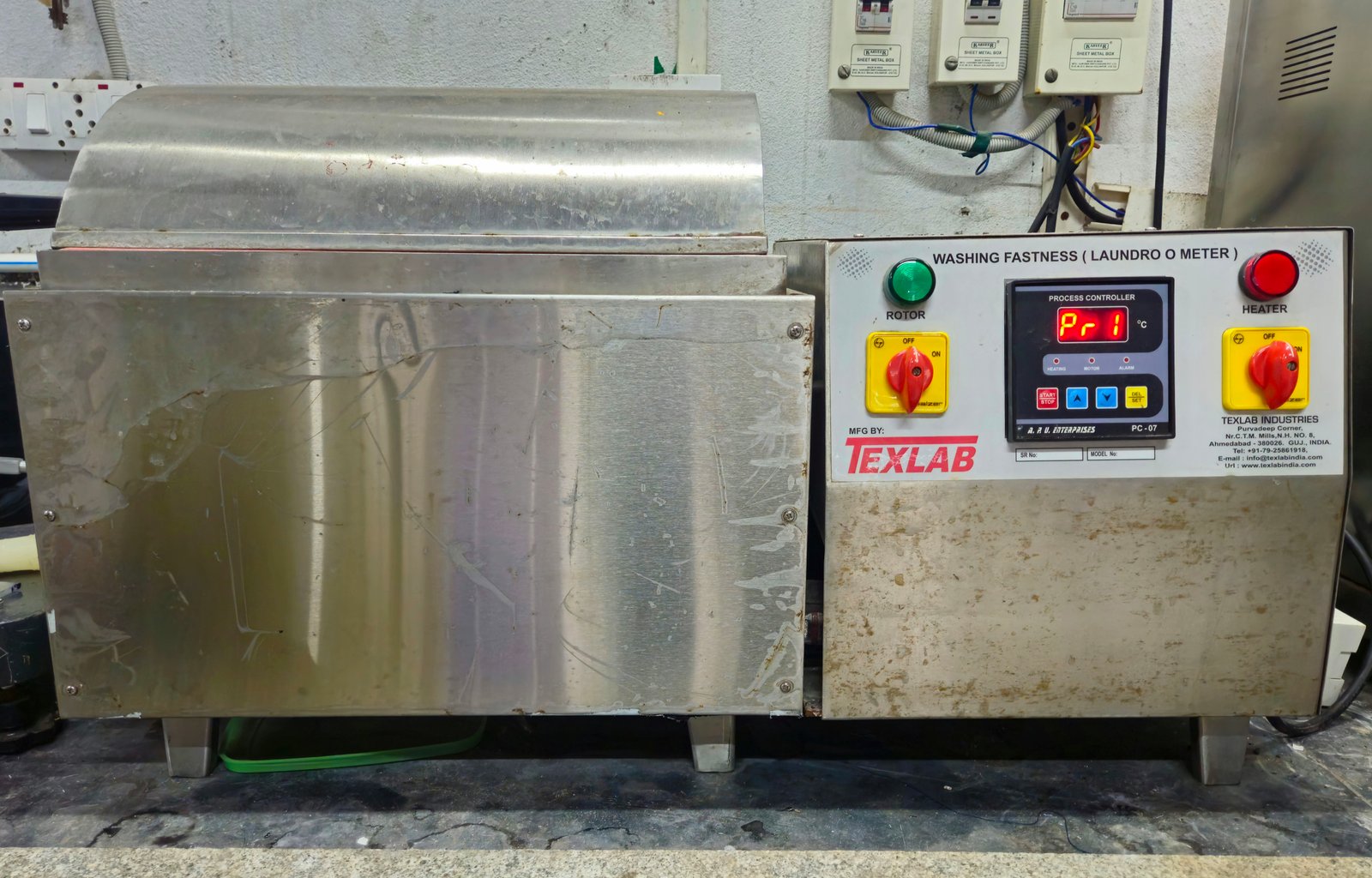

Launder-O-Meter

Tests color fastness to washing and dry cleaning according to international standards (ISO, AATCC), guaranteeing that colors remain vibrant and do not bleed.

Crock Meter

Measures the fabric's resistance to color transfer when rubbed (wet and dry). This ensures the color stays on the fabric, not on other clothes or skin.

Pilling Resistance Tester

Assesses the fabric's tendency to form unsightly pills on its surface after repeated wear and washing, ensuring a long-lasting, premium appearance.

Bosch Washing Machine

Simulates real-world domestic laundering to provide ultimate confidence in the fabric's dimensional stability and color fastness after multiple home washes.

Bosch Tumble Dryer

Tests for shrinkage, spirality, and appearance changes after machine drying, ensuring the garment maintains its shape and quality for the end consumer.